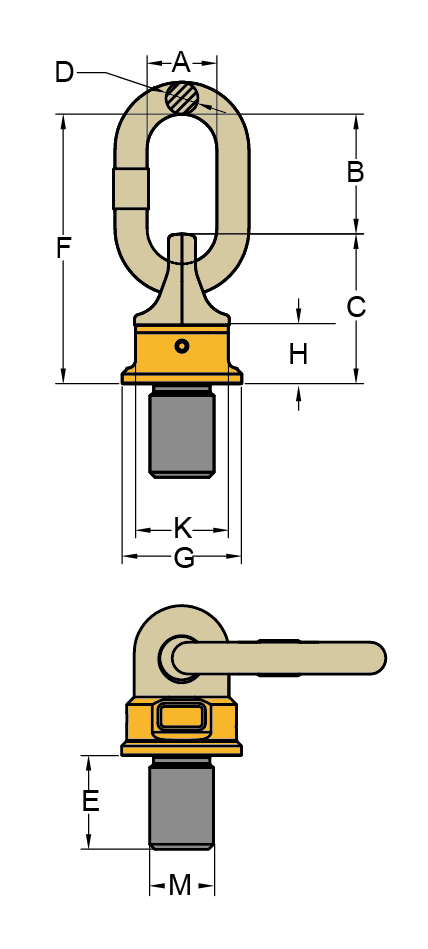

Pivots to 230°, rotates through 360° due to its unique ball bearing design.

Certified by DGUV GS-OA-15-04.

Load rated parts are 100% magnaflux crack detected.

Individual forged parts and batch code links to Test Certificate sheet.

Bolt are Metric thread (ASME / ANSI B18.3.1M).

Proof tested to 2.5 times the WLL.

Fatigue rated to 1.5 times the WLL.

All YOKE Super points meet or exceed all the requirements of ASME B30.26.

Easy to attach or dismantle due to the forged hexagon shaped body of the Super Point.

Capable of rotating under load.

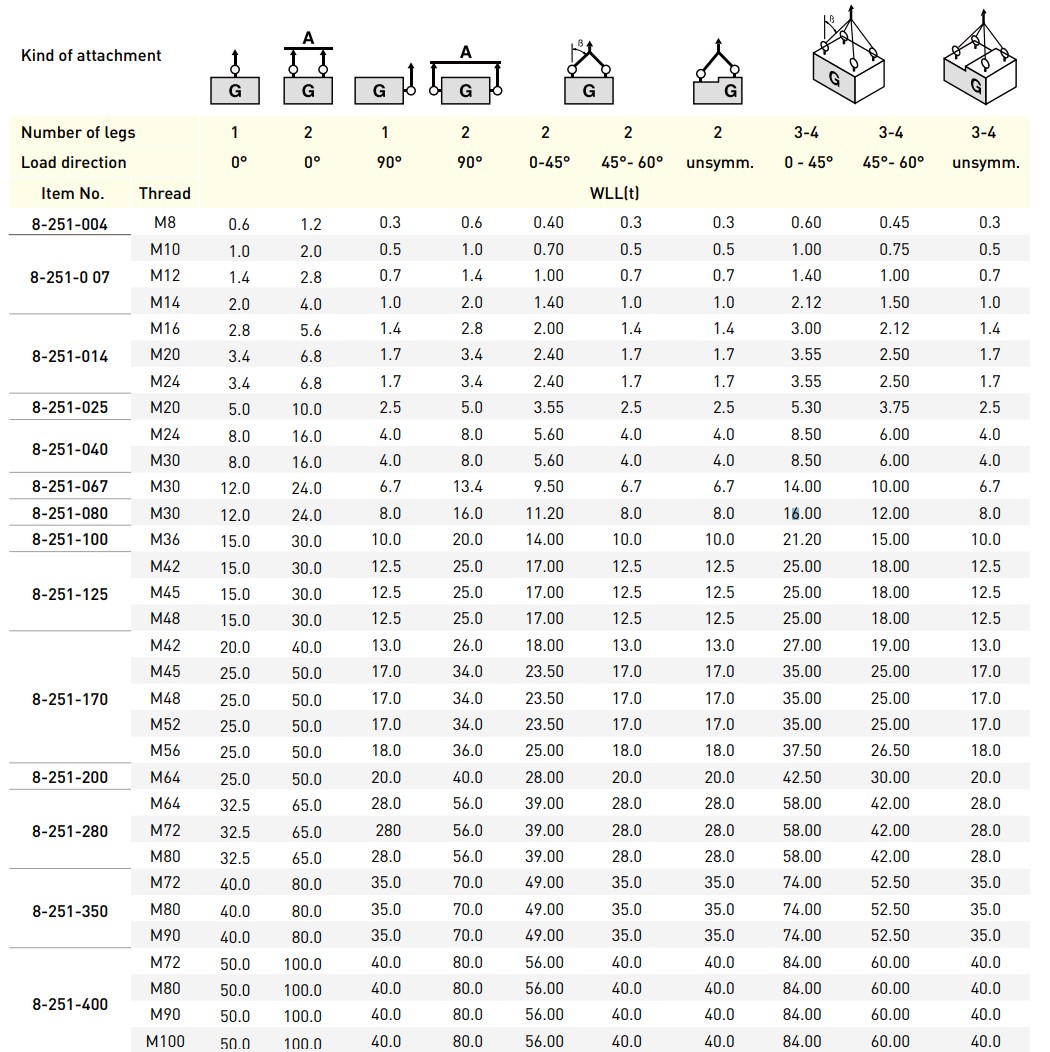

With the new WLL tables you can find the right Super Point attachment for your application and by the red marking on both sides you can measure disposal stage of the Super Point.

- Features: Built-in RFID/NFC chip

- Material: Forged alloy steel, quenched and tempered.

- Marking: According to standard, CE-marked

- Temperature range: -40°C - +200°C

- Standard: EN 1677-1

- Warning: Do not turn continuously in 90 degree direction at full load.

- Safety factor: 4:1