WEBBING SLINGS

WG PN-EN-1492-1

ROUNDSLINGS

WG PN-EN-1492-2

Choosing the right sling

When selecting and ordering textile slings - both serpentine and belt slings - it is necessary to take into account the required lifting capacity, use and type of load to be lifted. The appropriate selection of a sling depends on the size, shape, weight of the load, its intended use, working conditions and specific material.

The selected textile sling should be strong enough and have the appropriate length for the planned use. If multi-tension slings are used to lift a load, all tendons must be identical. It is important that there are no factors that are harmful to the sling material in the vicinity of the load.

Additional equipment and lifting techniques must also be considered when selecting a sling. A key aspect is the design of the sling, including the type of ends or types of loops.

If a sling with a flexible loop works with a hook or lashing, the minimum length of the loop must not be less than 3.5 times the maximum thickness of the hook or lashing. The angle formed in the loop must not exceed 20°.

When using a textile sling in conjunction with a lifting device, the part of the device on which the sling loop rests must be straight if the width of the sling support is less than 75 mm. The minimum radius of curvature of the attachment element should be at least 0.75 of the width of the sling support. Slings with larger widths may affect the inner radius of the hook, which may interfere with the even distribution of the load across the width of the sling.

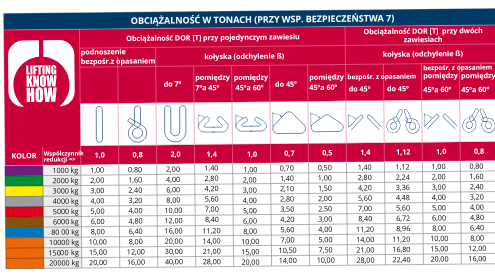

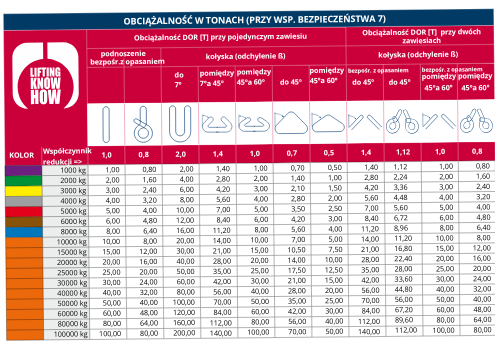

Avoid overloading textile slings by observing the correct mode factors (see table). Information on the permissible load capacity can be found on the sling's label. For multi-leg slings, do not exceed the maximum angle of deviation from vertical.

Protect textile slings from friction, abrasion and damage caused by the load, its corners or lifting devices. If the slings are equipped with reinforcements or safety guards, install them correctly. If necessary, additional safety guards can be used for greater durability and safety.

Use in harsh environments and hazardous conditions

Resistance to chemicals and harsh environments varies depending on the sling material. It is useful to know the characteristics of each material:

- Polyester (PES): Exhibits high resistance to most mineral acids, but is susceptible to alkalis. Used in acidic environments, but avoid contact with alkaline solutions.

- Polyamide (PA): Ideal for alkaline environments due to its resistance to alkalis. However, its susceptibility to mineral acids limits its use in such environments.

- Polypropylene (PP): A very versatile material that is resistant to most acids and alkalis. Particularly useful in applications requiring superior chemical resistance.

- Dyneema®: A high-tech material that is extremely resistant to both acids and alkalis, as well as to UV radiation.

Key warnings:

- Chemical solutions that initially appear harmless may become more aggressive through the evaporation process.

- Contaminated slings should be removed from service immediately and thoroughly inspected after washing.

- For slings with steel components (class 8/10/12), avoid contact with acidic environments that can cause hydrogen embrittlement.

Conditions of use and storage

Different sling materials have a specific temperature range for use:

- Polyester (PES) and Polyamide (PA): Operating range is -40°C to +100°C.

- Polypropylene (PP): Operates at temperatures from -40°C to +80°C.

- Dyneema®: Ranges from -50°C to +70°C for exceptional flexibility.

Additional tips:

- At high humidity and low temperatures, ice formation in fibers is possible, which can cause damage.

- Chemicals can alter the performance of slings, so it is important to consult with the supplier when using them in aggressive environments.

Preparation for use

Inspection before first use:

- Verify the technical condition of the sling and make sure it meets the order specifications.

- Verify that the product certificate is complete and complies with the marking on the sling.

- Ensure that the sling is properly registered and suitable for the intended application.

Adaptation to work:

- Select a sling according to the maximum working load (WLL), type of load and working environment.

- When using more than one sling, choose products with identical technical parameters.

- Use protective pads or additional safety features to protect slings from sharp edges and friction.

Lifting and loading operations

- Make sure the load is properly secured and stable before lifting.

- Conduct a test lift to make sure the load distribution is correct.

- Avoid sudden movements, jerks and overloading, which can damage the sling.

- Never drag the load along the surface to prevent abrasion of the fibers.

After surgery:

- Lower the load in a controlled manner so as not to load the slings unnecessarily.

- Store slings in dry and shaded areas, away from UV radiation, which can weaken their structure.