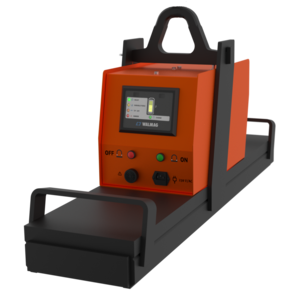

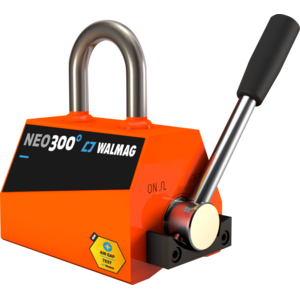

NEO HOT INDUSTRIAL PERMANENT MAGNET

The Neo HOT permanent lifting magnet is designed for a long life span even in the most demanding operations at working temperatures up to 180°C. Its design makes it possible to handle flat and round load profiles. The high lifting capacity is achieved by using a double magnetic circuit of strong neodymium magnets.

The EASY SWITCH design provides safe magnet switching. Operation of the magnet is very easy and can be done with just one hand. Emphasis is also placed on safety for the Neo Hot permanent lifting magnet: Testing is carried out by simulation of conditions in real operation, including the Air Gap Test. Even through the air gap, the achieved safety factor of this magnet (based on break-away test) is 3+. In other words, the maximum theoretical lifting capacity is equal to more the three times the nominal capacity.

The HOT series is a special design of permanent Neo lifting magnet intended for handling hot materials – burn parts, forgings, tools, workpieces, sheets, profiled sections, tubes, etc. It is noted for its high resistance when operated in difficult conditions and it makes it possible to handle loads at a temperature of up to 180 °C.

Advantages:

- Easy Switch control – the lifting magnet can be switched on and off easily, quickly, and safely.

- High resistance allows to operate the magnet in difficult conditions at temperatures up to 180 °C

- The double magnetic circuit with strong design neodymium magnets

- A compact body with only two recessed screws

- It has a low weight while retaining a high lifting capacity

- 5-year warranty for the magnetic systém

- Marking: According to standard

- Standard: EN 13155

- Safety factor: 3:1